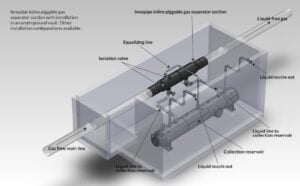

The image to the right shows several Innopipe systems that were delivered to one of our US clients.

The image to the right shows several Innopipe systems that were delivered to one of our US clients.

We have also installed Innopipe in places ranging from Kuwait to Colorado, from Brandon Manitoba to Indiana and India. We’ve tested them down to 1″ lines and installed them in up to 52″ lines.

Innopipe can be built close to wherever you’re installing and we have 100+ global installations that can attest.

Here are more details on this US installation and how it came to be.

The Problem To Be Addressed

This was a bit of a unique challenge, as the units had to be built within less than 2 months. The customer’s low-pressure HDPE pipeline was experiencing constant liquids accumulations.

Low pressure pipelines are often made out of HDPE pipe. These low pressure lines are suited to handle low pressure gas such as that produced from shallow wells or coal bed methane applications where a lot of water and/or condensate is produced. Economics often dictate liquids are not removed at the production site or wet metering is done and liquids remain in the line. Operational problems related to accumulations in low spots may result.

This in turn may cause back pressure on wells, reducing gas flow in the pipeline.

The standard approach for the removal of these unwanted liquids is large equipment like conventional gas/liquid separators or filters and coalescers. These applications are costly, less effective and more expensive to maintain than Innopipe separators.

This is a perfect application where Innopipe can make all the difference!

The Innopipe Solution

As Innopipe is designed in-house, designer and inventor Miles Haukeness quickly determined that designing and welding an HDPE version would take longer than using on-hand steel tubulars and heads.

We quickly drew up a steel piggable Innopipe that will insert into the client’s HDPE system and installed underground. Our ability to build to pipeline code or pressure vessel code allowed us to get the job done in time for the customer’s schedule.

Should you have a 2 phase gas/liquid problem requiring a negligible delta P, quick delivery, low cost, highly effective piggable or non-piggable solution for:

- Metering accuracy improvement

- Compressor protection/lube removal

- Tower carry-overs

- Pre-river crossing dewatering

- Corrosion prevention

- Black powder removal

- 1”-60″ lines

- Low points in pipelines

- Slug management

Contact Us For More Details

Are you a pipeline owner dealing with slugging, corrosion, or expensive maintenance in your LNG, steam, or natural gas pipelines?

Curious about how Innopipe can optimize your pipeline operations?

Innopipe makes it easy.

Our inline separators replace drips and remove liquids without the need for multiple steps, providing efficient performance.

We have an almost 3 decade track record at any pressure/temperature range you need.

Call OilPro Oilfield Production Equipment at +1 403 215-3373, [email protected], or visit www.Innopipe.com