Natural Gas wells often contain liquids which requires liquids management to prevent corrosion and sluggiing as well as flow rate control.

Natural Gas wells often contain liquids which requires liquids management to prevent corrosion and sluggiing as well as flow rate control.

Removing the liquid and sending it to tanks or parallel liquid lines post-Innopipe separation also allows for the gas to move down the pipeline without free liquids.As a result we mitigate causes such as freeze ups, increased pigging requirements, corrosion, slugging, metering and other issues.

There are a number of ways to remove these liquids, many of them more expensive than they need to be. New patented technology by Innopipe offers a less expensive separator design that removes these liquids using a natural phenomenon that occurs when gas is operating in the laminar flow condition occurring at velocities typically between 5 – 50 feet/second, yet is field tested and proven to provide turndown at rates well below.

Simply put, annular flow condition causes liquids to travel along the pipe diameter. Should mist be expected in certain sections, Innopipe offers solutions to knock these out as well.

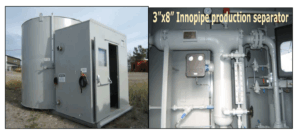

The Innopipe design takes this into account and removes these liquids into the liquid boot. This allows use of a smaller inline separator, as the velocity of the gas does not have to stop and drop out into a vessel to knock out liquids. Mist extractors are also not required as there is no violent action created by diverters or cyclones like in conventional separator.

Innopipe separators can be made to be piggable or non-piggable in any pressure range. A piggable Innopipe has a typical pressure drop across it of under 1 psi, and the non-piggable version stays within a 3-5 psi pressure drop. That means fewer horses needed for compression and fewer devices in a fail-safe system when using Innopipe.

Innopipe inline separators are available in sizes from 1” to 60” diameter.

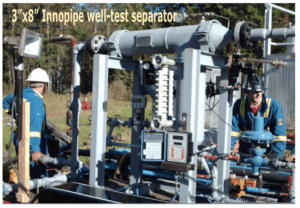

Facility sizes are reduced with Innopipe separators. Controls, metering and layouts can be set up to the requirements of the specific end-user AML (Approved Materials List). Innopipe separators were used to test over 300 wells with no liquid carry over. They work!

We have over 100 Innopipe installations globally in North America, Asia and the Middle East.

For more information on the Innopipe separator or the Innopipe pipeline liquid removal drip, contact OilPro at 1-403 215 3373 or email us at [email protected].