What purpose do oil separators serve?

Hydrocarbon streams as produced at the wellhead are composed of a mixture of gas, liquid hydrocarbons and sometimes free water.

In most cases, it is desirable to separate these phases as soon as possible after bringing them to the surface and handle or transport the two or three phases separately.

This separation of the liquids from the gas phase is accomplished by passing the well stream through an oil-gas or oil-gas-water separator. Selecting a separator for a hydrocarbon stream is based on the composition and properties of the fluid mixture.

In the case of low-pressure oil wells, the liquid phase will be large in volume as compared to the gas phase. In the case of high-pressure gas-distillate wells, the gas volume will be higher as compared to the liquid volume. The liquid produced with high-pressure gas is generally a high API gravity Hydrocarbon, usually referred to as a distillate or condensate.

What to do with the free water that occurs

Both low-pressure oil wells and high-pressure gas-distillate wells can contain free water. Separators are used in locations from wellhead production batteries, process plants, upstream and downstream of compressors, and as liquid traps in gas transmission lines.

Separators are also found on inlets to dehydration units, gas sweetening units et cetera. Common other names are knockout pot, scrubber, inlet or group separator, flash separator and a few more, but the design principle tends to be based on gravity separation where gas makes its way to the top, hydrocarbons end up in the middle and water falls to the bottom. (The only exception to this is when bitumen streams have specific gravities that are heavier than produced water)

All of the vessels mentioned above are designed to separate gas and free liquids and serve the similar purposes.

Key aspects of an oil separator

There are four key aspects of an oil separator:

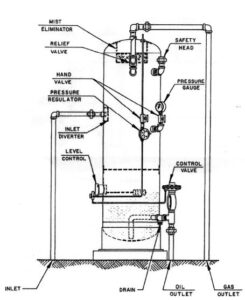

- An inlet diverting device for primary separation of liquid and gas without stirring up the vessel’s equilibrium

- A settling section of sufficient size to allow liquid droplets to settle out of the gas with adequate surge room for slugs of liquid.

- A mist extractor section or vane pack for high flow gas systems near the gas outlet that will coalesce and separate the small particles of liquid that will not settle out by gravity and retention time alone.

- Adequate controls consisting of a level controller, liquid dump valve, gas back pressure control valve, safety relief valve, pressure gauge, level gauge(s), instrument gas (or air) regulator(s) for pneumatic operation or more often now electric controls, and piping for each phase sized to match anticipated flowrates.

There are two common separator configurations: Vertical and Horizontal. OilPro has significant experience with both.

OilPro has significant custom oil separator capabilities

Separators are one of OilPro’s specialty areas. Custom-built separators with flexible design can be:

- Two-phase to three-phase separation design and occasionally four phase if solids are expected

- With or without slug capacity

- Dressed with stab-in controls or external cages

- Include ESD’s, electrical systems, SCADA and even export blocking and bracing and crating

OilPro’s standard separator inventory includes the following

- Vertical units up to 48″ diameter, in sweet or sour NACE-compliant designs

- Horizontal units ranging from 36″ through 96’ with larger custom ones available

- ANSI ratings up to 600 (1480 psig) typically in stock

- Custom sizes and pressure ratings are also available with expedited delivery available using our stock, pre-registered vessel designs.

- And if you’re replacing a failing piece of equipment, OilPro can help with that, too. Phone us we will build you a duplicate for an easy swap.

You can learn more about OilPro capabilities by checking our partners at Sivalls who have decades of experience in various aspects of onshore and offshore oilfield equipment for oil and gas producers dating back to 1947.

You can also contact OilPro directly at 403 215 3373 or by email at [email protected].