Glycols, such as ethylene glycol or propylene glycol, are commonly used as dehydrating agents in various applications because of their hygroscopic nature, which means they have the ability to attract and absorb moisture from their surroundings.

Glycols, such as ethylene glycol or propylene glycol, are commonly used as dehydrating agents in various applications because of their hygroscopic nature, which means they have the ability to attract and absorb moisture from their surroundings.

This property makes them effective in removing water from a wide range of materials, such as natural gas, air conditioning systems, and even in the preservation of food.

In the case of natural gas, glycols are used in dehydration units to remove the water vapor that is present in the gas stream. Water can cause several problems, such as corrosion, freeze-ups, and reduced gas quality, so it is crucial to remove it before the gas is transported through pipelines.

Below, we’ll discuss how oil & gas companies can benefit from glycol dehydration and how OilPro can help you get there.

Glycol dehydration process

Glycol dehydration is a process used in the oil and gas industry to remove water vapor from natural gas and other

hydrocarbon gases. Water vapor can cause several problems in the production, transportation, and processing of natural gas, such as corrosion, hydrate formation, and reduced heating value. Glycol dehydration is an efficient and widely used method to remove water vapor from natural gas, making it more suitable for transportation and use.

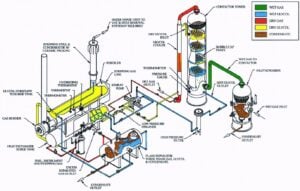

The glycol dehydration process involves passing the natural gas through a tower packed with a liquid desiccant, usually a glycol compound. The glycol absorbs the water vapor from the gas, and the dehydrated gas exits the tower.

The glycol solution then goes through a regeneration process where the water is removed, and the glycol is recycled back into the dehydration tower.

Glycol dehydration importance

The importance of glycol dehydration in the oil and gas business is significant because it helps ensure that natural gas is of high quality and suitable for transportation and use. The presence of water vapor in natural gas can cause problems during transportation, such as pipeline corrosion, blockages, and hydrate formation, which can lead to costly downtime and production losses.

In addition, the heating value of natural gas is reduced when it contains water vapor, which can affect the energy content of the gas and reduce its economic value.

Final thoughts

Glycol dehydration is a crucial process in the oil and gas industry to ensure the quality and suitability of natural gas for transportation and use.

OilPro stocks both new and re-manufactured glycol/gas dehydration units, which come with a one-year warranty. Options for dehydrators include:

- Flash gas separator,

- Various pump configurations

- 8-10 tray configurations.

Towers and re-boilers are often in stock and can be configured to your specific project requirements with production and packaging facilities in Alberta, and Saskatchewan, Canada,and directly from the Sivalls, Inc.facility in Odessa, TX for work off the North American continent.

We also are the authorized Sivalls, Inc. provider for the Middle East and North Africa (MENA) with the very best in glycol dehydration units with a proven track record.