1.0 VESSEL

TAG # QTY DESCRIPTION

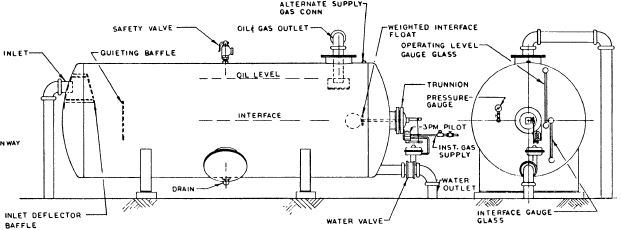

V-100 1 120" X 40'-0" S/S HORIZONTAL FWKO

To be Manufactured in 2014

Constructed with Alberta BC & Sask Registration

75 psi MAWP @ 200%u00B0F design temperature

1/8" C.A. on vessel & N.A. on Firetube

Radiography: RT-1

PWHT - None

Internally Coated - Devoe 253

VESSEL CONNECTIONS:

N3A Drain 1 - 2" XXH 150 ANSI Flange

N3B TI 1 - 2" XXH 150 ANSI Flange

N3C TC 1 - 2" XXH 150 ANSI Flange

N3D HTSD 1 - 2" XXH 150 ANSI Flange

N3E/F FG Preht 2 - 2" XXH 150 ANSI Flange

N3G PI 1 - 2" XXH 150 ANSI Flange

N3H/I Oil -LG 2 - 2" XXH 150 ANSI Flange

N3J/K H2Or-LG 2 - 2" XXH 150 ANSI Flange

N5 H2O Out 1 - 4" XXH 150 ANSI Flange

N6 Oil Out 1 - 6" XH 150 ANSI Flange

N7 Inlet 1 - 8" XH 150 ANSI Flange

N9A PSV 1 - 3" NPS 150 ANSI Flange

N9B Oil LLSD- sample-1 3" NPS 150 ANSI Flange

N9C Gas Out 1 - 3" NPS 150 ANSI Flange

N9D HLSD 1 - 3" NPS 150 ANSI Flange

N9E LLSD 1 - 3" NPS 150 ANSI Flange

N10 A/B/C Anode- 3 - 4" NPS 150 ANSI Flange

N10D Oil - LC 1 - 4" NPS 150 ANSI Flange

N10E Sample 1 - 4" NPS 150 ANSI Flange

N10F H2O - LC 1 - 4" NPS 150 ANSI Flange

Firetube 24" x 56' Nominal 1 - 3.5MMBTU Shop Built

M1a Oblong Firetube28" x 56" Shop Built

M2 Round MW 1 - 24" OD Shop Built

2.0 INSTRUMENTATION

NRG TAG # QTY DESCRIPTION

LLC-100/101 2 FISHER L2 LIQUID LEVEL CONTROLLERS

2" MNPT end connection

1 7/8" PVC Displacer

Snap acting Sour service

LCV-100/101 2 KIMRAY 425 FMT PO LIQUID CONTROL VALVE

4" 150# end connections

Sour service trim

Viton diaphragm and O-Rings

LG-100/101 2 PENBERTHY LEVEL GAUGE Bolted

Model 1TM9 ½" NPT

c/w 330J %u00BE" x ½" Gauge cock valves

PI-100 1 PRESSURE GAUGE

Liquid filled

4" dia. face x 1/2" NPT bottom mount end connection

SS case and internals

0 to 100 psig, dual scale

PSV-100 1 FARRIS PRESSURE RELIEF VALVE

3" 150# inlet x 4" 150# outlet K orifice

Sour service trim, WCB body

75 psig set pressure, mounted on vessel

ANO-100/101 4 ANODES

/102/103 3" X 22" X #17 Aluminium

c/w pigtail wires

TI-100 1 TEMPERATURE GAUGE

0 TO 250 F

3" dia. X 6" stem,

c/w ½" x %u00BE" x 6" thermowell

BPCV-100 1 KIMRAY 218 FGT BP-D BACK PRESSURE VALVE

2" 150# RF end connections

Viton diaphragm and O-Rings

Sour Service

PRV-300/301/302 2 FISHER 67CFR INSTRUMENT AIR REGULATOR

1/4" FNPT connections

STD service trim

250 psig MAWP, 5 to 35 psig spring range

Tapped Bonnets

2.1 BURNER SYSTEM NOTE: CSA B149.3 COMPLIANT CONTROLS

Field certification required

FABS-100 1 FLAME ARRESTED BURNER SYSTEM

Rated for 3.5MM BTU/hr to fit 24" firetube

C/w 4" thk flame cell element,

Eclipse burner

BMS-200 1 PROFIRE 2100

Combustion Safety Controller

SOV-201/202 2 SOLENOID VALVEs

24 volt, 1" NPT connections

SOV-200/203 2 SOLENOID VALVEs

24 volt, 1/4" NPT connections

TSH 200/ 1 TEMPERATURE SENSOR ELECTRIC

TSHH 200 Wika TC-10 Dual Head Thermocouple

%u00BE" X 1" X 12" Stem 304 stainless steel

PSHH/LL- 2 HIGH & LOW PRESSURE SWITCHES

200/201 Profire Burner System

High Pressure Switch (9 to 35 psi)

Low Pressure Switch (1 to 15 psi)

PCV-200 1 KIMRAY MOTOR VALVE

1400 SMT, 1" NPT Steel body,

½" EQ% SS trim

Minimum fire stop, TCV 205

PSV-201 1 MERCER PRESSURE RELIEF VALVE

Set @ 30 psig

1" NPT inlet x 1" NPT outlet

STD service trim, WCB body

LLSD-200 1 KIMRAY LEVEL SWITCH ELECTRIC

2" NPT connection c/w manual test switch

Sour service

PRV-200 1 FISHER MODEL 627 INSTRUMENT GAS REGULATOR

1" FNPT end connection,

Ductile Iron body construction,

3/16" SS orifice

5 to 20psig Outlet Range

PI-201/202/203 4 PRESSURE GAUGE

/204/205 Liquid filled

2 1/2" dia. face x 1/4" NPT end connection

0 to 50 psig range, Dual Scale

PRV-201 1 FISHER 67CFR INSTRUMENT GAS REGULATOR

1/4" FNPT connections

STD service trim

250 psig MAWP, 5 to 35 psig spring range

Tapped Bonnets

3.0 FUEL GAS SYSTEM (1" NPT OFF SKID SWEET SUPPLY REQUIRED)

V-200 1 10" OD X 30" S/S x 150 psi MAWP FUEL GAS SCRUBBER

Temperature range -20/650oF

2" NPT Outlet Connection, 1" NPT Inlet Connection, %u00BE" NPT Drain Connection,

Mechanical High Level Shutdown (Reduces 2" outlet down to 1" NPT)

CRN in AB, BC, SK, MB, ON

PSV-200 1 MERCER PRESSURE RELIEF VALVE

Set @ 150 psig

1" NPT inlet x 1" NPT outlet

STD service trim, WCB body

Mounted on fuel gas scrubber

PI-200 1 PRESSURE GAUGE

Liquid filled

2 1/2" dia. face x 1/4" NPT Bottom Mount connection

0 to 200 psig range, Dual Scale

4.0 MANUAL VALVE SPECIFICATIONS

QTY DESCRIPTION

4 4" 150# RF RP, Balon or Equivalent Ball Valves

2 2" 150# RF RP, Balon or Equivalent Ball Valves

2 1" NPT RP, 2000 PSI, Balon or Equivalent Ball Valves

2 ½" NPT Bar Stock Ball Valves

2 ½" Inline Stainless Steel Check Valves

1 ½" NPT 3000# MxF SS Needle Valve

8 %u00BC" NPT, 3000# MxF mini needle Valves

5.0 SKID & BUILDING SPECIFICATION

SK-100 1 SKID BASE, 10' W X 50'-0"L

Main skid members 8" X 12" X .375 HSS Tubing

12' 6" Wide x 14' Deep x %u00BC" checkerplate

(4) 10" Wide Flange @ 45# under vessel supports

4 Lift Lugs at vessel leg locations

1" drip lip around building area.

2" NPT Floor Drain.

B-100 1 SELF FRAMING BUILDING

12'- 6" wide x 14' deep, 13' Eave, Gable Roof Style

Vapor Barrier, Flame Retardant Insulation w/

Pre-painted steel exterior and aluminum liner.

Colors:White on white

(1) 3'-0" x 7'-6" Door c/w, IWG, check chain, panic hardware, and weather-stripping,

Two (2) 12" x 12" Adjustable Louver,

One (1) 3' x 3' sliding window

Ice Rakes, Eavestrough, downspouts.

6.0 MATERIAL SPECIFICATIONS

Vessel Material

Vessel Head & Shell SA-516-70

Welded Internals SA-36

Bolted Internals SA-36

Internal Components

Studs / Nuts / Washers 316SS

Mistex pad 316SS

Internal Piping

Studs & Nuts SA-193-B7M / 2HM

Nozzles SA-105N Flanges / SA-106-B Pipe

Preheat Coil SA-234-WPB Fitting / SA-106-B / SA-105-N

Gaskets Duralon 8500 / 316 SS Flexatalic / Buna N

Manway SA-53-B, ERW

Firetube

Firetube SA-106-B

Firetube Flange SA-516-70N

Firetube Studs & Nuts SA-193-B7M / 2HM

Firetube Washers 316SS

Welded Piping

Pipe SA-106-Gr.B SMLS

Flanges SA-105-N

Weld Fittings SA-234-WPB

Studs & Nuts SA-193-B7M / 2HM

Threaded Piping

Pipe SA-106-B, Sch. 80 SMLS

Threaded Fittings SA-105-N, 3000#

Instrument Tubing

Tubing 316 Stainless Steel

Fittings Stainless Steel

Ferrules Stainless Steel

8.0 PAINT AND COATING SPECIFICATIONS

Vessel

External Surface Preparation SSPC-SP#3

External Primer One (1) Shop Coat

Vessel External Finish Paint Two (1) Shop Coats of Grey Enamel

Internal Surface Preparation SSPC-SP5

Internal Coating Devoe 253 Installed as per manufacturer's specifications

Skid and Piping

External Surface Preparation SSPC-SP#3

External Primer One (1) Shop Coat

Skid and Piping External Finish Paint Two (1) Shop Coats of Grey Enamel

Water Out & Drain Out Lines: Devoe 253

Flanged Valves on Water & Drain Impreglon 222

Flame Arrestor Stacks: High Heat Warm Gray

Insulation

• Areas not covered by the building are covered with 1-½ inches of high density fiberglass and clad with 020 aluminum

9.0 TESTING / PWHT SPECIFICATIONS

Hydro testing

Pressure Vessels Hydrotested to 1.3 Times Maximum Allowable Working Pressure as per ASME Section VIII

Pressure Piping Hydrotested to 1.5 Times Maximum Allowable Working Pressure as per B31.3

Radiography & NDE

Vessels RT- 1

Nozzles None

Internal Piping None

External Piping 100% X-Ray

Firetube 100% X-Ray

UT on Cat D Welds None

MPI Firetube only

Hardness Testing None

PWHT

Vessels No

Piping No

Firetube No

10.0 EXCEPTIONS & CLARIFICATIONS

- We have included a single man door, and single window in the building

- The layout of the package does not facilitate the second double door and window.

- Potentially a second window could be added, but this space is currently set aside for the electrical junction boxes.

11.0 QUALITY CONTROL PACKAGE

1. Vendor data included:

- Two (2) CDs containing

QC data

parts list

as-built drawings in pdf format.

- One (1) hard copy of parts list stored inside each package

12.0 DELIVERY Vessel Material on Order

DELIVERY: 16-17 WEEKS ARAD

TO BE CONFIRMED AT TIME OF ORDER

SUBJECT TO PRIOR SALE

Show Less