We are starting to hit cold snaps as winter hits the continent for another season. SOLARIS kept critical systems on multiwell pads going below -40C.

We are starting to hit cold snaps as winter hits the continent for another season. SOLARIS kept critical systems on multiwell pads going below -40C.

Getting there wasn’t easy.

At first, we didn’t understand the need for a new solar hybrid system for critical remote power.

Wasn’t that available already?

Aren’t there enough companies stuffing seacans already?

Well, yes, but there is a lot of half-baked, untested product, so at the urging of one of our loyal clients, we designed and built a robust, certified and tested for remote, cold weather operation system. Bentek’s Applications Engineering Team and OilPro got to work on SOLARIS.

Component testing revealed why so much of what’s out there are one-offs and simply doesn’t work. Nameplate ratings were more often indicative of ambition than field-proven capability.

Bentek’s engineers tested and tested until they confirmed consistent repeatable performance and found controllers, chargers and gensets capable of remote site, critical reliability.

What’s Changed?

As high bleed pneumatics were displaced with low-bleed, those are now being replaced with electric controls. Facilities design changed radically. Reliability of DC-powered instruments and controls improved a lot over the last 2 years. Competition improved outcomes, increased operator confidence, and adoption of 12-24VDC power. Operators now run multi-well pads, meter wells, and control separators with fewer Watts than ever before.

While an instrument air package will always have a place at larger facilities, sites with 10-well pads are now run as all-electric facilities with no need for pneumatics. Deleting part of the process and simplification optimizes design. Less component interdependence and fewer of them increases reliability.

Low power requirements and smaller enclosures mean less heat is needed for low temperature genset starts. Low backup generator run hours (30-300 hrs/year) negate slippage considerations vs continuous duty generation systems.

What Do You Get with SOLARIS?

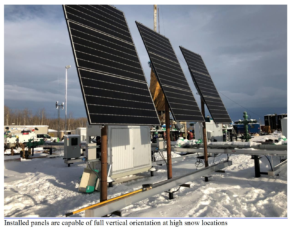

Solar Panels

· Shade tolerant, low temp, high efficiency, wind & snowload rated

· 360 degree horizontal and angle adjustment to full vertical

· Linear power, low internal current, low spot temperature solar cells

· ISO 9001 and CSA-approved

UPS

· Modular Ah, AGM, no-spill, with thick plates

· Cold climate rated from -40C to +50C

Controller, Inverter, Electronics & Connections

· Modular design incorporating microprocessors with built-in diagnostics

· High PV to battery efficiency, high energy harvest

· NEMA-4 enclosures, JB’s for backup power, Web enabled

Genset

· Commonly available, simple, durable air-cooled, hydraulic lifter engine

· Built-in diagnostics, remote start, dry air, cartridge oil filter

· Easy scheduled maintenance with no special skill requirements

· National Park Service guideline sound level compliant, UL 2200 listed

· Propane fuel only to mitigate emissions and royalty reporting

Skid and Building

· 5 sided reach-in access enclosure for simple service

· Fire retardent, corrosion and rodent resistant, vented panels

· Base skid with lifting lugs, floor and gas heater w. thermostat, hood, shut-off

Communications

· Web montiroring, satellite or cellular

· MODBUS, RS485 · SCADAlink by Bentek, tested and proven across N-American critical power and communications infrastructure.

Engineering, Certification, Drawing, QC/QA

· All included + CSA General Area Certificate

The Result

SOLARIS provides a turnkey solar hybrid package proven to deliver critical solar-electric power year round, supported intermittently by a genset that sees only 30-300 hrs of duty per season. Occasional generator power for electric heat tracing and supplemental charging automatically steps in during cold snaps or extended low light periods.

This duty cycle means only scheduled maintenance is required. Operations proceed uninterrupted. Operators get sleep, production continues day and night.

Maintenance is easily scheduled, and fewer admin hours are spent on emissions and wellhead gas production and conditioning or reporting for a cleaner, more predictable, easily serviced bottom line.

To learn more, call OilPro at +1 (403) 215-3373, Bentek at +1 (403) 243-5135 or send your mail to [email protected], or [email protected]