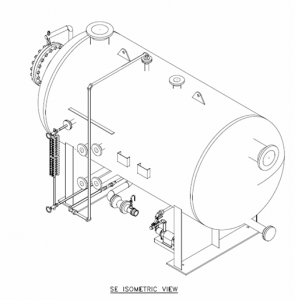

FKOD-36x84-H-SWEET-10BBL-50#-SKonly PKG (FKOD-3050)

Flare Knockout Drum, 3' x 7', Sweet Service, 10 Bbl capacity, 50 psi Design Pressure, internally coated, SK Reg'd.

OilPro Oilfield Production Equipment Ltd.

Flare knockout drums, or FKO's for knocking out any liquids upstream of a flarestack, are stocked in sizes ranging from five through 100 barrels. Pressures ranges include atmospheric and ASME code, ABSA -certified vessels. OilPro draws stock from a variety of sources in order to offer the best value available at any time. Scroll below for what's available.

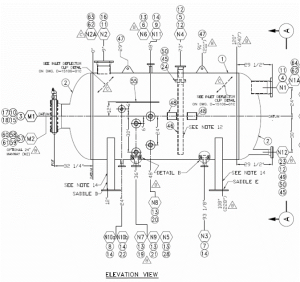

Design Considerations:

Design Considerations: Nozzles

Nozzles

Flare Knockout Drum, 3' x 7', Sweet Service, 10 Bbl capacity, 50 psi Design Pressure, internally coated, SK Reg'd.

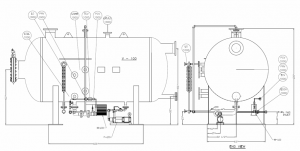

OilPro's stock design sour 10 Bbl, 50#, multi-configurable FKOD

Flare Knockout Drum, 4' x 10', Sweet Service, 25 Bbl capacity, 50 psi Design Pressure, SK Reg'd.

OilPro's stock FKOD line features:

BC, AB, SK, MB Canadian Registration in place

Can be configured with or without a skid

Containment tray is integral to design

Bi-directional

Over […]

96"ID x 10' S/S FLARE KNOCK OUT VESSEL

Originally built for Pembina Pipelines for underground service

To be custom packaged with quick delivery for above-ground service or left as is.

• […]