In our last article we discussed the CAP3-F remote power configuration in detail. In this article we’ll focus on the CAP3-M configuration and why you might consider it for your remote power needs.

Introducing Compressed Air Pneumatics (CAP3)

This is the second in a series of three articles discussing the Qnergy Compressed Air Pneumatics (CAP3) remote power solution distributed by OilPro across Canada.

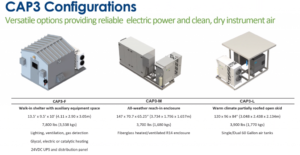

We’ll discuss all three solutions to consider. In this second article we’ll focus on the CAP3-M. It’s a less-expensive model with similar performance as the CAP3-F Walk-in Shelter with auxiliary equipment space and the higher electrical output. The smaller air output Nano CAP3 model is also available which we’ll discuss next in the third and final article on CAP3 configurations.

The Compressed Air Pneumatics product line first came to light when OilPro profiled its prototype at the Global Energy Show in 2019. The product evolved significantly since as you now have three product lines to choose from which now include HMI’s and world class integrated SCADA integration and monitoring of genset and air systems.

Let’s focus on the CAP3-M for this article and why you might choose it over the CAP3-F and CAP3-Nano options.

Why choose CAP3-M for your remote power needs?

- Same performance as F-model but in reach-in enclosure

- Lower cost due to reduced enclosure size and no personnel entry requirements such as LEL and gas detection

- Site design can accommodate items like custom RTU’s etc. in other available enclosures.

- GHT option available

Qnergy CAP3-M standard features from OilPro

| Area class rating | General purpose |

| Temp rating | -40°C to 40°C (45°C option) (-40°F to 104°F (113°F option) |

| Skid DIMS (with PowerGen) | 94”W x 115.4”L x 65.7”H 2.43mW x 2.93mL x 1.66mH |

| Cabinet DIMS (standalone) | 45”W x 115.4”L x 62.7”H 1.14mW x 2.93mL x 1.59mH |

| Weight | Full Skid Weight: 2550 lbs CAP3 M Cabinet weight: 1500 lbs (excluding PowerGen and skid) |

| Heating | 1250 W Electric Gravity louvre with air filter |

| Ventilation | Filtered Intake |

| Exhaust fan | Forced Air with rain hood |

| Enclosure insulation | R12 |

| Warranty | 1 year CAP / 3 yr FPSE (Free Piston Stirling Engine) |

| Certification | SPE1000 / cETLus |

Generator (PowerGen Option)

| Generator tech | Free Piston Stirling Engine |

| Generator power | 5650 W |

| Generator voltage | 120/240 VAC 60Hz |

| Fuel consumption (NG) | 1300-3964 SCF/d / 38-112 m3/d |

| Gas conditioning unit | Heat Traced liquid KOP |

Control

| Control | Micro PLC / 7” HDMI with UV rated cover |

| PowerGen communications | Smartview / Modbus TCP |

Instrument Air System Specifications

| Standard | High Pressure (HP) | High Temperature (HT) | |

| Compressor | Duplex oil-free | Duplex oil-free | Duplex oil cooled |

| Compressor CFM | 15.2 @ 100 psi | 12.5 @ 145 psi | |

| Maximum pressure | 116 psi | 145 psi | 150 psi |

| Maximum temperature | 40°C | 40°C | 45°C |

| Dry tank capacity | 80 gallon (303 l) | 80 gallon (303 l) | 132 gallon (500 l) |

Air tank capacity: Desiccant Dryer – minimum 25°C dew point suppression

Air meter: Thermal Mass Flow Sensor

Maintenance interval: Once per year

Emergency power: Manual Transfer Switch

System Operations Specifications

| Standard Configuration 120/240VAC | High Flow 3-phase, 240VAC | High Power | |

| Operating pressure range | 80-100 psig | 80-100 psig | 80-100 psig |

| Dry air capacity (duplex operation) | 10.5 SCFM (18 SCFM) | 12 SCFM (24 SCFM) | 5.8 SCFM |

| Auxiliary power | 1kW @ 120VAC | 1kW @ 220VAC | 2.4kW @ 120VAC |

Summary

The federal government in Canada gives oil & gas firms incentives to reduce emissions with initiatives like the Emissions Reduction Fund – Onshore Program. CAP3 instrument air systems are an excellent solution.

You can also learn more about reducing your carbon footprint by clicking here.

Want to learn more?

Contact OilPro at +1 403 215 3373 or contact us by email at [email protected]. We’ll help you learn more about how a Compressed Air Pneumatic system combining a low-maintenance scroll compressor with a virtually zero maintenance Qnergy Stirling engine, battery charging and a storage system will not only help your operations team comply but increase runtime while reducing freeze-ups caused by power outages or pneumatic line blockages.