Does your company adhere to ESG (Environmental, Social and Governance) performance metrics?

While ESG metrics are already being used by companies to compensate staff, in 2020 it also became more prevalent in terms of investing. Both managed investment funds and individual investors now take a closer look at companies and how their business dealings impact the environment.

Companies themselves are increasingly tying executives compensation packages to a formula involving ESG performance metrics, too.

Would you like to learn more about ESG metrics and how your business can adhere to them to do your part to help the environment while also separating yourself from competitors in a real way?

From OilPro’s perspective, your ESG strategy will come down to optimized engineering design for your specific site requirements. We understand the nuances of integrating such technologies at an existing but also a clean slate new facility.

Brownfield applications require a different approach than new sites, with solutions ranging from simple instrumentation philosophy changes to physical modifications to equipment and facility design to accommodate ESG goals.

We have interfaced with end-users and their engineering consultants our entire careers and are prepared to collaborate for the best informed outcomes.

Let’s take a closer look at ESG metrics and how OilPro can help you achieve them.

ESG: Your business and your competitors

Take a look at your competitors’ website and see if you can find at least one reference to how their business practices are carbon neutral or otherwise environmentally friendly.

Many companies like to tell their visitors that it’s something they can offer. People increasingly consider the environment for personal reasons or as mentioned above, when looking at a potential investment.

And if you don’t find any such reference to the environment on your competitor’s website, you’ve got a leg up on them and can differentiate yourself by highlighting how your business practices are environmentally friendly.

Here’s how OilPro enables you to get a better handle on ESG performance metrics to help you and the environment.

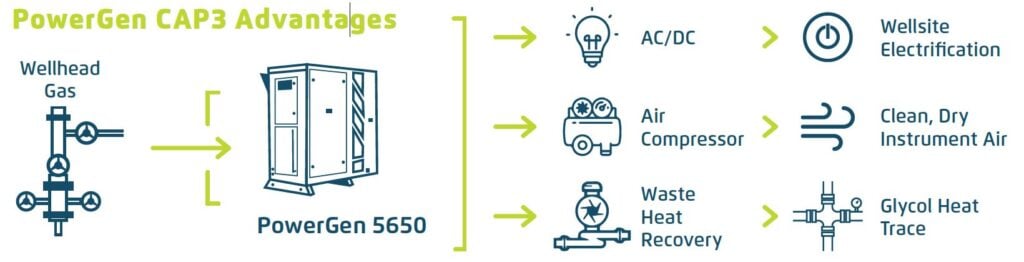

PowerGen

- PowerGen provides reliable remote energy at a better cost than traditional generators for numerous applications.

- Efficient power vs conventional energy sources such as ICE (internal Combustion Engines)

- Electric power completely replaces pneumatic power.

- Surplus power goes to SCADA, Radio, injection pumps, lights, electric heat tracing on site.

- GHT (Glycol Heat Trace system captures waste heat turning system in to micro CHP (Combined Heat and Power) system with 70-90% overall efficiency.

- Minimizes refuelling and maintenance requirements with commensurate lifetime carbon footprint reductions.

- Helps you lower your total carbon footprint in other ways while also increasing the efficiency of your choice of remote power, too.

CAP3

- Compressed Air Pneumatics (CAP3) enables you to replace methane emissions from pneumatic devices with the more environmentally friendly compressed air.

- Compare instrument air vs 24 x greater polluting methane instrument pneumatics and you can see how CAP3 can lower your methane gas emissions and help you meet government and corporate goals.

- All the same benefits as the freestanding PowerGen unit.

- Click here to check out a recent OilPro install of our new CAP3 Nano instrument air system + 3000 Watts with a heat trace option.

Bolted Tanks

- A bolted tank eliminates the need for heating and environmental controls during welded tank erecting.

- Bolted tanks offer an excellent alternative for storage of liquids and dry goods and can be customized as you require.

- All OilPro bolted tanks include our proprietary coating process so that every square centimeter of each bolted steel tank is factory powder coated to protect against corrosion.

Updated design glycol dehydrator systems

- Higher tray counts in process towers mitigate emissions of BTEX (Benzene, Toluene, Ethylbenzene and Xylene, all known carcinogens) which reduces overall GHG effect from gas drying systems.

- By adding more trays, glycol circulation is reduced as is uptake of BTEX, and subsequent emissions of these harmful hydrocarbons during the glycol regeneration cycle in the reboiler.

- Take a look at the custom Glycol Dehydrator built by OilPro for the Southern Alberta Institute of Technology (SAIT).

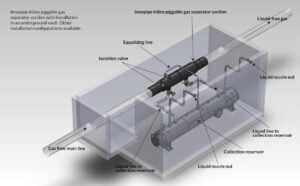

Innopipe

- Drastically reduces the size of equipment required to remove liquids from gas transmission lines

- Less steel and smaller physical footprint means lower carbon inputs.

- Innopipe only interrupts 10% of the pipeline diameter vs. 100% with conventional systems, meaning there are fewer compressor horsepower losses due to lower pressure drops within the system overall, further reducing carbon taxes on fuel and carbon footprint.

VRU

- OilPro supplies complete packages for Vapour Recovery Compressor packages and Vapour Recovery Unit (VRU) system based on ease of use and operation.

- These capture waste gas from API storage tanks thus eliminating venting of raw gas.

- We can power systems as low as 5 HP compressors, which is below what anyone else builds meaning we can eliminate venting from smaller grid- isolated sites.

Want to learn more about how to lower your total carbon footprint, do better for the environment and use it as a competitive advantage?

Call us directly at 403 215 3373 or contact us by email at [email protected] for more details.