Vent gas mitigation is a term that those in the oil & gas sectors should expect to hear more about moving forward. It’s a subject that is facing increased regulations incl uding in Canada from the federal Government.

uding in Canada from the federal Government.

Vent gas mitigation refers to the process of reducing or eliminating the release of harmful gases from vents in industrial or commercial facilities. These vents are typically used to allow excess gases or vapors to escape from tanks, pipes, or other equipment.

There are several methods that can be used for vent gas mitigation, including:

Flare systems: Flare systems burn off excess gases, reducing their release into the atmosphere.

Pre-flaring gas processing: with VRU, dewpoint depression or Venturis

- Vapour Recovery Units remove otherwise vented tank vapours and compress them for on-site processing such as compression to add to the sales gas stream.

- Dewpoint depression or refrigeration by mechanical means or the Joule-Thomson Effect (JT) will cool the gas stream, drop out valuable liquids and send lighter ends to either the onsite sales gas stream, gas re-injection stream or to flare as a last resort.

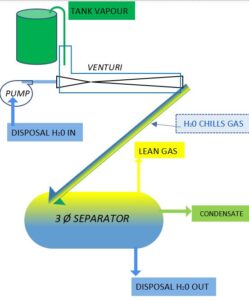

- Venturis can achieve much of the same effect as VRU’s but use a motive fluid such as high pressure gas or liquid to remove low pressure gas, compress it and feed a further process. One added benefit from Venturi-based VRU systems occurs when water is used as the motive fluid. The water’s ability to absorb heat from the compressed gas stream enables it to realize a third phase (gas composition permitting), namely condensate which can be blended with other on-site streams such as sales oil, as illustrated below.

The specific vent gas mitigation method used will depend on the type and concentration of gases being released, as well as the specific regulatory requirements, economics of the site, ability to process and market gas, or re-inject gas for formation pressure conservation purposes and environmental conditions at the facility.

Overall, the goal of vent gas mitigation is to minimize the impact of venting systems to the environment above and below ground.

What is the difference between venting and flaring?

Venting and flaring are both methods of releasing gases that are produced during industrial processes or waste treatment. However, there are some key differences between the two:

Purpose: Venting is the release of gases into the atmosphere through a venting system. The purpose of venting is usually to relieve pressure or to allow gases to escape.

Flaring, on the other hand, is the controlled burning of gases. The purpose of flaring is to safely dispose of gases that cannot be recovered or recycled. The most ideal method for flaring is actually incineration where 99.99% of gas can be considered to be destroyed into inert constituents.

Emissions: Venting can result in the release of harmful gases into the atmosphere, which can have negative impacts on the environment and human health. Flaring, on the other hand, can significantly reduce the amount of harmful gases released into the atmosphere, as the gases are burned and turned into water vapor and carbon dioxide in an ideal situation. In practice flares are affected by wind and variable gas compositions.

Equipment: Venting systems are typically simpler than flaring systems, as they do not require the same level of temperature and ignition control. Flaring systems typically consist of a burner, a flare stack, and ideally an incinerator to control the burn.

Overall, the main difference between venting and flaring is the purpose and the impact on emissions. Venting is used to release gases into the atmosphere, while flaring and incineration is used to safely dispose of gases through controlled burning.

Summary

Companies in the oil & gas sector increasingl focus on reducing emissions in conformance with new regulations.o. The issue of vent gas mitigation is one example that oil & gas firms will need to pay close attention to and deal with to avoid running afoul of the law. The question is, how to do it?

OilPro offers a number of options for oil & gas companies to reduce and mitigate gas and emissions they produce. From flare knockout drums to environmentally friendly remote power options like PowerGen to our newest tank emission reduction solution, OilPro can help you get there.

Contact us directly at 403-215-3373 or by email at [email protected] to discuss your specific concerns.